We invest in the design process to simplify your product

Our unique “Design to Simplify” process starts with passion, skill, and intelligence. We internalize the user’s unmet needs and discover windows of opportunity. We design products that bring passion, talent, and a creative approach to solving our customers’ challenges.

“Design to Simplify” is a holistic approach that streamlines and simplifies both the design process and the product. Our “Design to Simplify” process means reducing your project to its most basic elements:

• User expectations

• Functional requirements to meet expectations

• Manufacturability requirements to make the product profitable

By simplifying the industrial design process in this way, you’ll take products to market that perfectly balance user expectations with production and profitability requirements.

Project Start Up: “Users and their needs start the dialogue.”

Identify the obvious problems

Engage in user-centered research

Observe end users and their environment to develop a product profile

Evaluate and analyze the information

Identify problems that are not obvious

Act upon the real problems

Conceptual Design Development: “Let’s count the ways we can deliver on the user’s expectations.”

Generate an expansive collection of working concepts

Create exploratory studies in 3-D

Research material options

Analyze spatial considerations

Analyze marketplace trends

Build life-size models

Product Design Refinement: “Let the best ideas prevail.”

Consolidate best ideas from concept development

Refine design, features, form, and materials

Develop branding strategy, colors, textures, and graphic elements

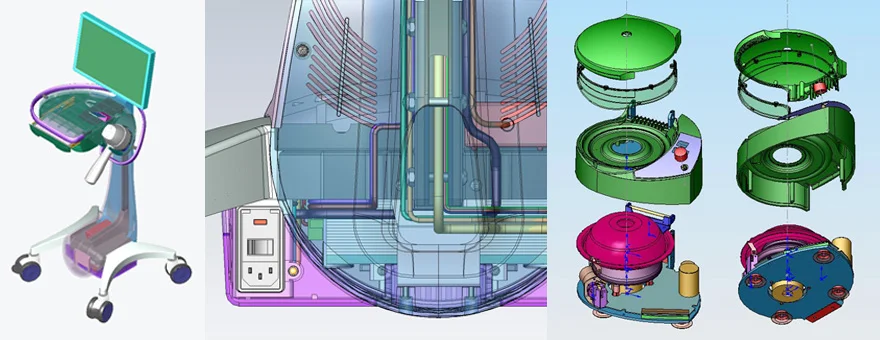

Generate CAD models

Build surface models

Build final appearance models and surface modeling

Identify suitable materials, manufacturers and suppliers

Detailed Design Engineering: “Move from the abstract to the tangible.”

Evaluate manufacturing requirements

Evaluate engineering requirements, component specifications, GMP, and materials

Generate final CAD part modeling and assemblies

Generate quote packages

Perform cost estimation and analysis

Design Prototyping: “Build prototypes to test the best ideas and work out the kinks before production.”

Analyze production processes

Build and evaluate prototypes

Complete final engineering design

Develop implementation approach

Manufacturing & Vendor Liaison: “Set the stage for production.”

Research and identify potential suppliers and manufacturing resources

Evaluate candidates and provide recommendations

Prepare RFQ packages

Review detailed tooling and molding requirements

Review final manufacturing specifications

Establish comprehensive team integration

Evaluate first production parts